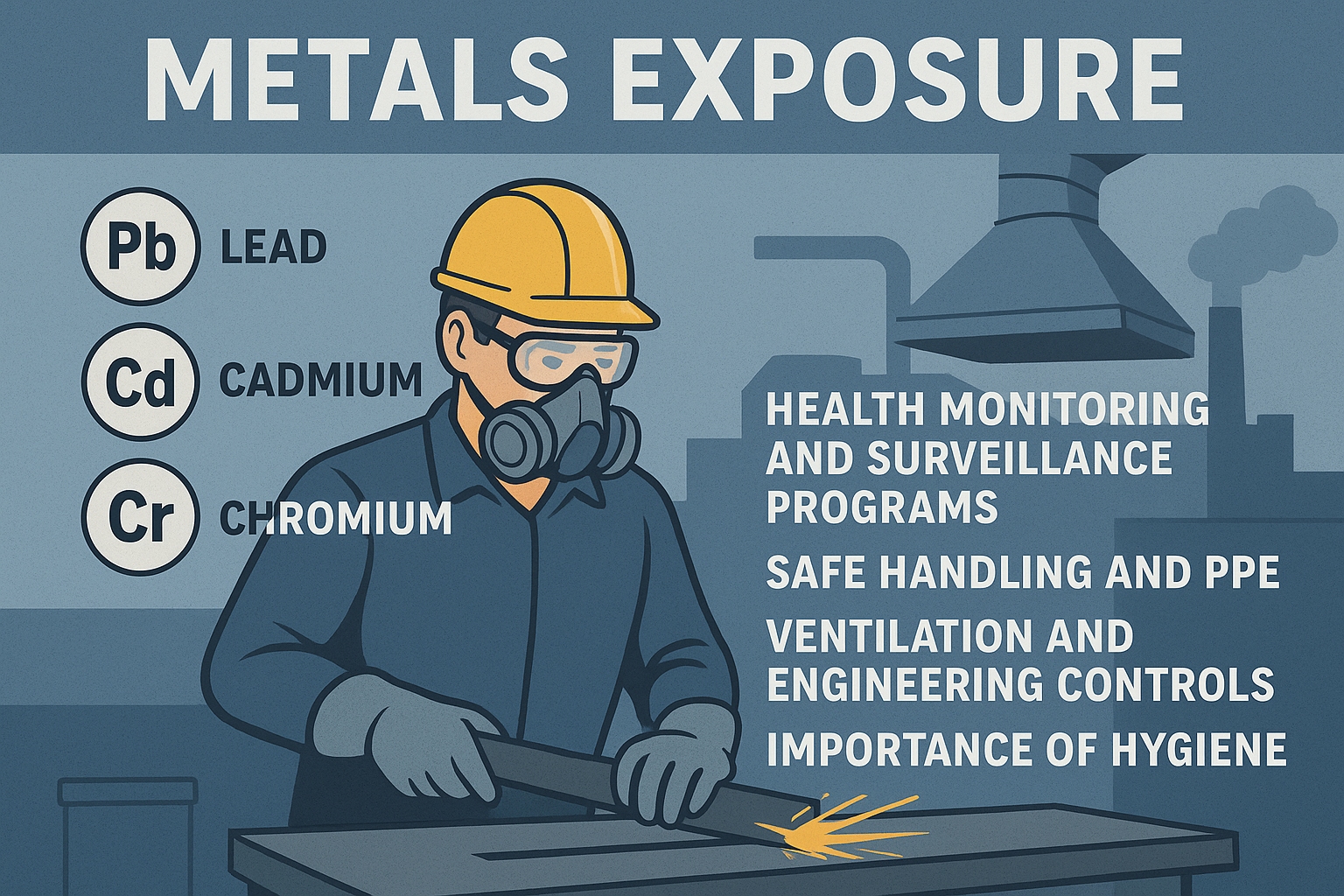

In industrial environments, metals such as lead, cadmium, and chromium are indispensable in many processes. They are used in construction materials, coatings, welding, plating, and various forms of manufacturing. Yet, while these metals provide functional and economic value, they carry with them serious health and safety risks if exposure is not effectively managed. Many of these risks are not immediately visible; symptoms of overexposure often develop gradually, sometimes going unnoticed until severe damage has already been done. This makes it essential for both employers and employees to understand the hazards, implement preventive measures, and establish a strong workplace culture of health protection.

Risks of Lead, Cadmium, and Chromium Exposure

The dangers of metal exposure differ depending on the type of metal, but all carry long-term consequences if left unchecked. Lead exposure, for instance, has been widely studied and remains one of the most common occupational hazards in industries such as battery manufacturing, painting, and construction. Chronic exposure to lead affects the nervous system, kidneys, blood production, and reproductive health. Workers may experience fatigue, headaches, irritability, and reduced concentration, while prolonged accumulation can cause irreversible organ damage.

Cadmium presents another layer of concern. It is a toxic metal and known carcinogen used in batteries, pigments, electroplating, and plastics. The most significant risk comes from inhalation of cadmium dust or fumes during activities like welding or soldering. Acute exposure can cause severe lung irritation, while long-term exposure primarily targets the kidneys and lungs, often leading to chronic lung disease or cancer.

Chromium, especially in its hexavalent form (Cr(VI)), is a highly hazardous substance found in stainless steel production, electroplating, and anti-corrosion coatings. Exposure can occur through inhalation of dust or fumes or through direct contact with skin. The consequences range from respiratory issues and skin ulcerations to lung cancer and other systemic diseases. Because Cr(VI) is particularly aggressive in damaging tissues and altering cellular structures, it is tightly regulated in many countries.

The risks from these metals are compounded by the fact that exposure routes include inhalation, ingestion, and dermal absorption. Without proper controls, workers can unknowingly take metals home on clothing or skin, creating secondary exposure for their families. This ripple effect makes prevention even more critical.

Health Monitoring and Surveillance Programs

Given the serious health implications, employers must establish robust health monitoring and medical surveillance programs. These programs are not just about compliance; they are about early detection and prevention. Medical surveillance often begins with a baseline assessment when workers first join a company or are assigned to metal-exposure tasks. This provides a point of reference for future health checks.

For workers exposed to lead, regular blood lead level tests are essential to ensure exposure remains within safe limits. For cadmium, urinary cadmium and beta-2 microglobulin tests help monitor kidney function, while chromium exposure may require lung function testing and urinary chromium assessments. In addition to biological monitoring, periodic clinical examinations allow occupational health specialists to identify subtle symptoms such as respiratory irritation, skin rashes, or neurological changes that may be linked to overexposure.

Health surveillance programs should be supported by environmental monitoring, including air sampling in work areas and personal exposure monitoring devices. This ensures that exposure levels are tracked not just at the individual level but across the workplace. Crucially, results from these programs must lead to actionable decisions: adjusting work practices, improving ventilation, revising PPE requirements, or rotating staff to reduce prolonged exposure.

Safe Handling and the Role of Personal Protective Equipment

While engineering and administrative controls remain the preferred methods for controlling exposure, personal protective equipment (PPE) is a necessary safeguard in many situations. Proper PPE use begins with understanding the tasks at hand and the type of exposure likely to occur. For example, workers cutting or welding metals should wear respiratory protection capable of filtering metal fumes. Depending on the exposure level, this may range from N95 respirators to more advanced powered air-purifying respirators (PAPRs).

Skin protection is equally important, as metals can be absorbed through contact or cause irritation. Workers should be provided with impermeable gloves, long-sleeved protective clothing, and safety footwear designed to resist contamination. For eye and face protection, goggles or face shields are critical during grinding, welding, or plating operations.

One often overlooked but essential measure is the use of dedicated work clothing. Regular uniforms or personal clothes can carry metal dust home, contaminating vehicles and living spaces. Employers should provide on-site changing areas and laundry services, ensuring work clothing remains confined to the workplace. Just as important is worker training: PPE is only effective if employees are instructed in its proper selection, use, limitations, and maintenance.

Ventilation and Engineering Controls

Although PPE is critical, the most effective line of defense against metal exposure is through engineering controls. Ventilation systems, especially local exhaust ventilation (LEV), are designed to capture metal dust and fumes at the source, before they spread into the breathing zone of workers. For example, welding stations fitted with extraction hoods or booths can drastically reduce airborne concentrations of lead or chromium fumes.

In addition to LEV, enclosure and isolation of processes can minimize exposure risks. High-risk operations such as electroplating or cadmium smelting should be performed in contained environments with restricted access. Where possible, employers should also consider substitution—using less hazardous materials in place of lead-based paints or cadmium alloys.

However, even the most advanced systems are only effective when properly maintained. Filters, ducts, and extraction fans require routine inspections and cleaning to ensure they function as intended. Employers should establish a scheduled maintenance program, along with regular exposure assessments, to verify that engineering controls continue to perform effectively.

Importance of Hygiene in Preventing Metal Exposure

Workplace hygiene plays a surprisingly large role in controlling metal exposure. Even small lapses in hygiene can result in ingestion of harmful substances. For this reason, strict rules against eating, drinking, or smoking in work areas must be enforced. Food and beverages can easily become contaminated by airborne dust or by contact with contaminated hands, leading to unintentional ingestion of metals.

Workers should also be provided with adequate washing and decontamination facilities. Simple measures such as washing hands and face before meals, or showering before leaving the workplace, can drastically reduce the risk of internal exposure and prevent take-home contamination. Employers should create designated clean areas for eating and drinking, away from work processes that generate dust or fumes.

Housekeeping is another critical element. Metal dust can settle on floors, equipment, and surfaces, creating a persistent source of exposure. Regular cleaning using wet methods or vacuum systems with HEPA filters is far more effective than dry sweeping, which can re-suspend dust into the air. Training workers on these hygiene practices and embedding them into daily routines ensures that safety measures remain effective.

Final Thoughts

Metals such as lead, cadmium, and chromium are invaluable to many industries, but their benefits come with serious risks. The dangers of overexposure are not always immediate, which makes them particularly insidious. By the time symptoms appear, significant damage may already have occurred. This reality highlights the importance of a comprehensive exposure control strategy that blends engineering solutions, PPE, health monitoring, workplace hygiene, and continuous training.

Ultimately, managing metal exposure is about more than compliance with regulations—it is about safeguarding the workforce and preventing long-term health crises. Employers who prioritize these protections not only ensure the well-being of their teams but also build trust, reduce liability, and foster a culture where safety is valued as much as productivity. In the end, protecting workers from hidden hazards is both a moral obligation and a strategic investment in sustainable operations.

At Rinath HSE Hub, we provide practical tools such as Environmental and HSE Registers to help organizations identify hazards, assess risks, and stay compliant with industry standards. If you want to strengthen your workplace safety programs and protect your workforce from hidden hazards like metal exposure, explore our ready-to-use resources today on our website.

Athenatus Ricky

Athenatus Ricky